The AWTHS received a inquiry concerning the Arcanum Racquet Factory recently. In corresponding with Gwenyth G. Haney, the Collection Manager with Dayton History, we received the following information regarding the Dayton Racquet Company which was the forerunner to the Arcanum plant.

For those of you familiar with Arcanum history or who attended the Racquet Factory program last fall at AWTHS given by Barb Deis, this will give further insight into the forerunner of our village’s history. AWTHS also has a binder about the factory in our reference library as well as the video from the 2022 program on our FB page for our viewers and followers.

This article is posted with prior permission and the contents therein are to be credited to the Dayton History organization if shared or used in any manner and the Carillon Historical Park.

We also received communication and visits from Conrad Klank here at AWTHS who owns a small business in Dayton and sells tennis themed gifts and accessories. Through his inquires with the Dayton History organization and communication efforts thereafter, Conrad visited AWTHS and met with several past employees of the Arcanum Racquet Company. Maybe we will have a future story about their experiences as well!

Dayton Steel Racquet Company History-

On January 17, 1922, William A. Larned, a 7-time United States Tennis Champion, fulfilled a long-time dream of his in Dayton, Ohio. Larned had been developing the idea of a steel tennis racquet for several years. Historically, athletic racquet frames (tennis, badminton, squash, etc…) had all been made of wood and the strings were made of animal intestines. This meant that the racquets were susceptible to damage from breakage, warping, and stretching. Larned had determined that with a steel frame and strings, all of those problems would go away and the timing for the switch to steel and wire couldn’t have been better. The introduction and seemingly meteoric rise of the America’s adaption of German sausages had quickly become a staple snack found at nearly every sporting event and public gathering across the nation. This resulted in a great strain on the supply chain for gut casings, which were used to make both racquet strings and those delectable meaty treats known as hot dogs.

Larned, pitched his idea for the new all-steel racquets and found investors in Dayton including the likes of Charles E. Kettering, George B. Mead, G.M. Williams, and Harry and Nelson S. Talbott. Having raised enough investment capital, Larned created the Dayton Steel Racquet Company, which began manufacturing the new racquets in Dayton and distributing them to sporting goods stores across the globe through the already well-established retailer, the A.G. Spaulding Company.

The early designs of the new racquet did not perform as well as hoped, so some modifications were made. The end result was a steel framed racquet with specially twisted wire strings. The new design meant that the racquet’s cross section was smaller than that of the older wooden racquets, resulting in a lighter weight racquet with less wind resistance. The specially twisted metal wire strings provided the racquet face with a degree of stretch much like that of the natural gut stings, but with a greatly extended life span as the wire strings were much stronger and less likely to break. The specially twisted string design was one of Larned’s own patented designs. In all, Larned himself held ten U.S. patents regarding this invention and his company would be awarded six more for their product designs before the end of 1931.

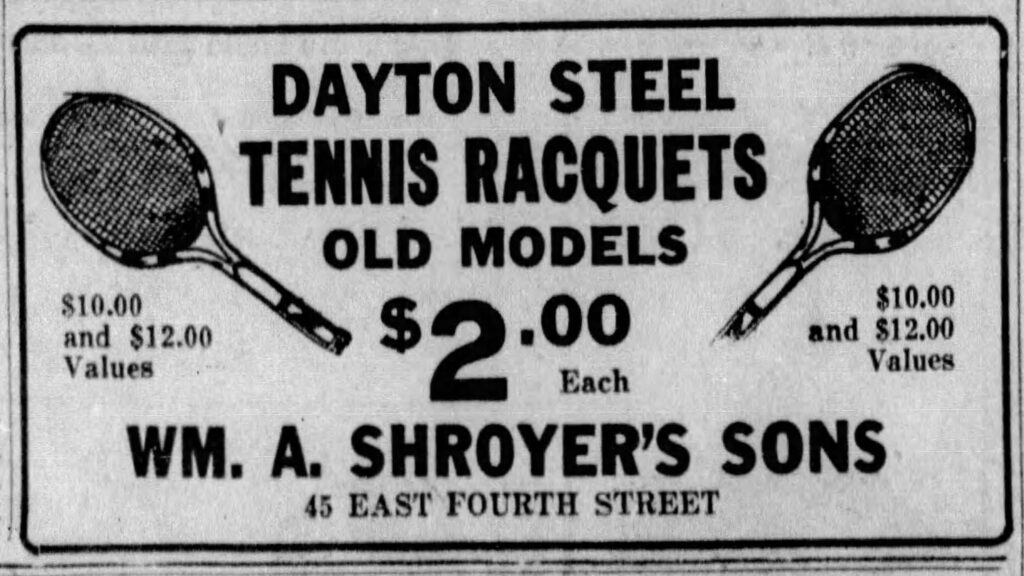

The steel racquet was a success and word traveled fast among professional athletes and amateurs alike. The new steel frames were originally made by the Pneumatic Tool Company in Dayton- which happened to be one of Albert B. Hilton, Jr.’s companies (A.B. Hilton Jr. was one of the Dayton Steel Racquet Company’s Vice Presidents.) Only the handle was made of wood, and the racquets sold for between $10.00 – $13.50. The factory was located on Miami Chapel Road, while the business offices were located in the Callahan Bank Building. In a relatively short period of time, a new manufacturing facility was needed and the company moved to a location on Ray Street.

Sales continued to increase throughout the rest of the year and by February 1923, Nelson Talbott, then President of the company, set his sights on opening sales offices in London and Paris, with hopes of opening more offices in South America as well. In 1926, international tennis legends Gerald Patterson and Billy Johnson travelled to Dayton to tour the factory and place orders for custom-made racquets. Incidentally, in December of that same year, the company founder and tennis pro William Larned committed suicide in New York City. In 1911, he had been diagnosed with rheumatism which eventually led to the paralysis of his legs, cutting short his tennis career.

Other types of racquets and steel archery arrows were added to round out the product line. By 1928, sales had increased another 50% so the decision was made to incorporate the company and sell stocks to raise the funds necessary for an expansion of the facilities. Unfortunately, their timing would prove far from ideal because as the October 1929 Great Stock Market Crash wiped out a significant amount of the nation’s wealth. The Dayton Steel Racquet company was also a victim of the crash as their product sales slowed, the money they had borrowed for the expansion had come due and the banks demanded repayment of the company’s debts. By December 1930, the company was placed in receivership, with an outstanding debt of more than $160,000.00. A petition was filed with the Montgomery County common pleas court and the company was reorganized with R. B. Munday named President and appointed as receiver. R.B. Munday was a successful businessman having run the Dayton Friction Toy Company and several other local concerns. Production of the steel sporting goods continued in Dayton under his management until, he moved the business in 1934 to Arcanum, Ohio, about 20 miles northeast of Dayton. The company continued manufacturing racquets throughout the next six decades.

During World War II, the company became a sub-contractor for Inland Manufacturing, producing bolts for the Carbine rifles that were made and assembled at the Inland plant in Dayton. At the company’s peak during the war, they employed 245 people and were awarded the very prestigious Army-Navy “E” award for excellence on July 5, 1944. R.B. retired from the business in 1945 and his brother E. Louis Munday became the sole proprietor.

The business continued production in Arcanum until the mid-1990s. Changes were made over the years as new developments were made in the sporting goods industry; for example, the steel racquets gradually fell out of favor with the pro players and instead became a favorite found at playgrounds and recreational centers across the nation thanks to their reputation for durability. The last racquet made by the company was produced in 1995.

Please follow AWTHS blog guidelines.